By fulfilling these objectives, FAT safeguards operational efficiency, promotes safety, and protects investments. FAT is a critical step in ensuring that equipment meets all specifications, functions correctly, as well as complying with industry standards. When you buy equipment from S3 Process, our engineers will support you through the entire FAT and SAT process.

How to Write a FAT Document

A Factory Acceptance Test (FAT) document is the cornerstone of a well-organised FAT process. It outlines every aspect of testing, ensuring all stakeholders align on objectives, procedures, and expected outcomes. Below is a detailed guide to writing a robust FAT document with practical examples.

Introduction

The introduction section sets the stage for the FAT process:

- Objective: ” This Factory Acceptance Test has been produced by [Company} in accordance with cGMP manufacturing guidelines. This document defines the procedures to validate the [equipment name], ensuring compliance with [specific project requirements] before shipment.”

- Purpose: Provide a concise statement of why the FAT is necessary. For example: “The FAT ensures the equipment meets performance, safety, and quality standards, reducing risks during installation and commissioning.”

Clearly articulate the significance of the FAT to all involved parties.

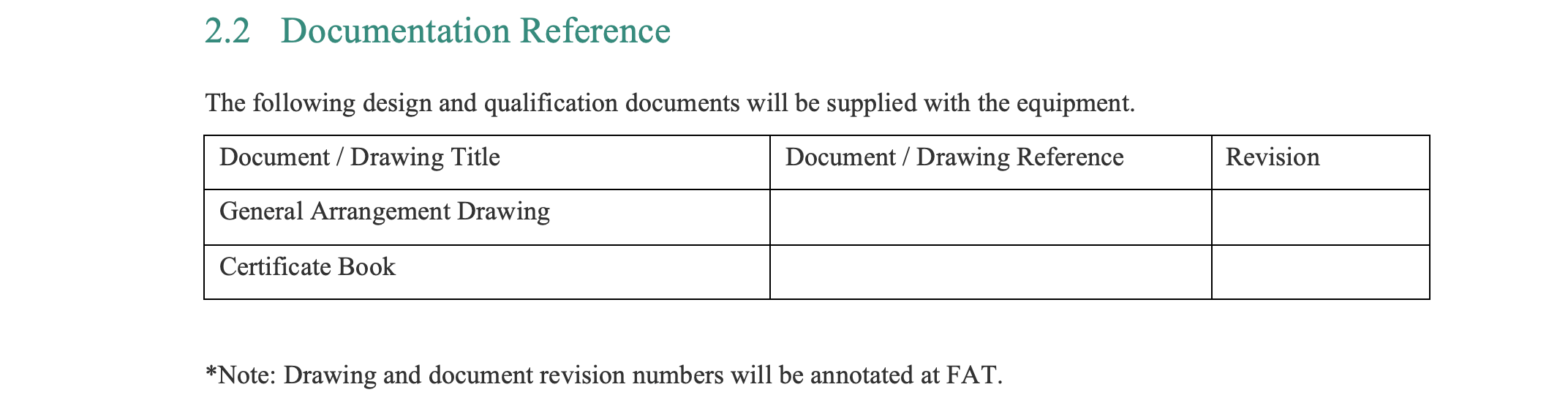

Documentation References and Definitions

Ensure consistency by referencing relevant standards and definitions (this can also be included in a glossary section at the end of the document):

- Standards: Include industry norms such as ISO 9001 for quality management or IEC standards for electrical safety. For example: “Tests will follow IEC 60204 standards for electrical safety.”

- Definitions: Define key terms and abbreviations. For example: “MTBF (Mean Time Between Failures): The predicted time between system breakdowns.”

- Contractual References: Include references to purchase orders, design documents, as well as regulatory requirements.

This section ensures all participants understand the scope and expectations.

Scope of Tests

Define the boundaries and objectives of testing:

- In-Scope: Detail what will be tested or “Test Content”. For example: “Mechanical testing will verify rotational tolerances and material strength. Electrical testing will ensure compliance with voltage limits and current draw.”

- Out-of-Scope: Important! If any specific tests are excluded clearly state and clarify these exclusions. For example: “Site-specific programming adaptations and external piping integration will not be tested.”

This clarity ensures focus and prevents scope creep.

Areas to Be Tested

List the specific systems under evaluation:

- Mechanical: Evaluate moving parts, structural integrity, and component alignment. For example: “Verify the conveyor belt maintains tension at 500 kg load without slippage.”

- Electrical: Test wiring connections, voltage regulation, and system grounding. For Example: “Measure voltage drop across connections at 80% load to ensure <5% deviation.”

- Software: Assess interface usability, logic sequences, and error handling. For example: “Confirm the control panel responds within 0.5 seconds to emergency stop commands.”

Overview and Test Plan

Provide a roadmap for conducting tests:

- Sequence tests logically. For example: “Start with mechanical alignment tests, proceed to electrical compliance checks, and conclude with system integration testing.”

Test Philosophy

The Test Philosophy section of an FAT document provides a structured approach for conducting and recording test results. It ensures consistency, traceability, and clarity in the testing process. Below is a step-by-step guide to writing this section effectively.

- Define the Testing Format: Clearly outline the components of the test documentation, such as test result sheets, failure reports, and corrective action tracking.

- Detail the Test Result Recording Process: Explain that Test Result Sheets will be used to document the outcome of each test. These sheets should indicate whether a test was successful or not, with space for comments on failures.

- Outline the Procedure for Failed Tests: Describe how Test Failure Report Sheets will be generated if a test fails or cannot be completed. These sheets should specify the reason for failure and required corrective actions.

- Summarize the Failure Review Process: State that a Test Failure Report Summary Sheet will be compiled after testing. This document should list all failed tests, corrective action deadlines, and track the re-testing process until completion.

- Address Non-Test Issues and Change Control: Include a Further Action List to document any non-test-related issues, such as design modifications or functional changes. Attach any relevant Change Control records.

- Define Test Completion and Certification: Conclude by stating that once all tests are satisfactorily completed, a Factory Acceptance Test Certificate will be signed by the client witness and a representative of the equipment company, confirming successful FAT execution.

Following these steps, your final Test Philosophy section should look like this:

Personnel Requirements

Identify roles, responsibilities, and outline expertise needed for the tests to be successfully executed.

- Process Engineers: Ensure technical specifications are met. For example: “Verify agitator speeds align with the specified range of 50–300 RPM.”

- Maintenance Engineers: Focus on maintainability and durability. For example: “Assess ease of access for replacing wear components like seals or bearings.”

- Procurement Staff: Confirm compliance with purchase agreements. For example: “Check that material certifications match order specifications.”

Make sure to include contact details for all key personnel.

Specification of Individual Tests

Provide detailed descriptions for how each test and the outcome will be documented, this should be standardised format.

- Test Reference: A unique identifier assigned to the test. This can be a reference title or test number that corresponds to the testing plan.

- Title of Test: A clear but concise title describing the test. The title should indicate the specific function, parameter, or system feature being evaluated.

- Test Run Number: A sequential number that identifies each test run, starting from 01. This ensures a clear record of test repetitions.

- Controlling Specification Reference: A cross-reference to the controlling specification that defines the test requirements. This ensures alignment with design and performance criteria.

- Test Description: A brief summary of the test’s purpose, detailing the features, systems, or components under evaluation. This section should state what the test aims to verify.

- Pre-Requisites: Any actions which must be carried out before the test can be executed. This will include test equipment, documentation, and settings of the equipment under test.

- Data to be Recorded: A description of the test specific data to be collected and recorded. This may include comments relating to the test but must include serial numbers of any test equipment used to enable traceability to calibration certificates, copies of which be attached to this document where relevant.

- Test Result: Pass or Fail

- Comments: This section records any actions that are required to be carried out after the test has been completed.

- Tester and Witness Signatures: Lastly each test shall be signed and dated by the tester and the witness.

Key Considerations

- Each test must have clearly defined steps and measurable outcomes to ensure reproducibility.

- Data recording should be precise to support traceability and validation.

- Test failures must be documented with detailed reasons and corrective actions.

Data Entry and Documentation Standards

Ensuring clear, accurate, and accountable data entry is critical in Factory Acceptance Test (FAT) documentation. The following standards must be followed to maintain traceability, compliance, and consistency.

Personnel Identification

- All individuals entering data must be identified within the protocol.

- Each test must be signed and dated by the tester and a nominated witness.

Corrections and Amendments

- Corrections must be made by drawing a single line through the previous entry.

- Each correction must be initialled and dated.

- Ticks and crosses are not permitted—the tester must initial the appropriate response for accountability.

- Unused boxes or comment sections must be struck through with a single diagonal line, marked as ‘Not Applicable’ (N/A), and initialled and dated.

Date Format and Data Entry

- Dates must follow the format: DD/MM/YYYY (e.g., 15/01/2025).

- Each entry must be an original statement—photocopies or reused data are not allowed.

Supporting Documentation

- Photocopies of supporting documents (e.g., calibration certificates) must include:

- Test reference number

- Reference to the original source

- Initials, date, and page number

- Computation records (e.g., printed reports) must also be annotated with the test reference number, source, initials, date, and page number.

Annotation and Verification Standards

A colour convention ensures consistency when annotating or verifying documents:

| Verification Status | Method |

|---|---|

| Verified as Correct | Yellow Highlighter |

| Verified Unable to Check | Red Ink Strike Through |

| Verified Incorrect | Blue Highlighter |

| Amendments & Corrections | Blue Ink |

Comments and Review Process

- Non-compliant findings must be documented as comments, signed and dated.

- If additional space is needed, comments should be continued in an appendix, individually numbered in the same format as the protocol.

- Reviewers and approvers must provide initialled and dated responses where necessary.

Equipment and Utility Requirements

Advance preparation avoids delays during testing. List necessary resources for testing, make sure to include:

- Utilities: needed power/ gas supplies if necessary.

- Tools: Any additional tools needed to carry out the tests.

- Safety Equipment: Any safety equipment needed at site and/or to carry out tests.

E.g. “The equipment and services required to carry out this Factory Acceptance Test are as follows:”

- “Compressed air at 8 bar, 240V power supply.”

- “Torque wrench, multimeter, vibration analyser.”

- “Fire extinguisher, PPE, first aid kit.”

Tests Listing

Example:

Test Procedure and Results Sheets

A FAT plan should include comprehensive test scripts with clear, step-by-step instructions for each test. These scripts outline the methods, criteria, and expected results for each test.

- Test Name: Clearly identify the test being performed (e.g., “Motor Load Test”).

- Objective: State the purpose of the test (e.g., “To verify the motor can handle the specified load without overheating”).

- Methodology: Describe the steps to be taken during the test (e.g., “Gradually increase the load on the motor until it reaches the specified limit of 150% capacity”).

- Acceptance Criteria: Define the conditions under which the test is considered successful (e.g., “The motor should operate within the designated temperature range and with no signs of failure”).

- Expected Outcome: Specify what the expected results are (e.g., “The motor should reach full load capacity without failure, and the temperature should not exceed 80°C”).

Also include space for comments and signatures. Below is an example of a test results sheet.

Signatures Identification Page

this section captures the acknowledgments and approvals from key personal to ensure formal agreement on any outcomes.

Appendices

Attach any supplementary materials such as Diagrams/drawing and schematics, calibration certificates and/or reference manuals

Factory Acceptance Test Certificate

Provide an official summary of results:

- Include:

- Equipment name

- Test outcomes

- Deviations and resolutions

- Authorised sign-offs

Example: “This certificate confirms [equipment name] has passed all required FAT procedures and is approved for shipment.”

Why FAT Documentation Matters

Comprehensive FAT documentation is critical for operational readiness. It provides a detailed record of test outcomes, approvals, and actionable recommendations. Additionally, accurate and complete FAT documentation builds confidence among stakeholders and sets the stage for successful commissioning.

Challenges in FAT and Solutions

Frequently Asked Questions about Factory Acceptance Testing (FAT)

1. What is the primary purpose of FAT in manufacturing?

FAT ensures equipment meets the agreed-upon specifications and functional requirements before shipment.

It provides an opportunity to identify defects, verify performance under real-world conditions, and confirm that the equipment is ready for operational use.

- Verifies that the equipment operates as expected as well as meeting customer requirements

- Identifies any flaws or defects before shipment, reducing future downtime

- Confirms compliance with industry standards and regulations

2. What tests are commonly included in FAT?

Common tests during FAT involve checking equipment performance, safety, and functionality.

For instance, a generator might undergo tests for electrical output, load response, and safety features like shutdown procedures.

- Electrical performance tests (e.g., verifying voltage output)

- Mechanical performance tests (e.g., engine start-up)

- Safety checks (e.g., low oil pressure protection)

- Environmental tests (e.g., performance under temperature changes)

Each test ensures that the equipment can handle real-world conditions and operates safely

3. How do you document FAT results, and why is this important?

FAT documentation is critical for ensuring transparency and future review.

It provides a detailed record of the tests conducted, results, and any corrective actions.

- Test plans detailing the scope and criteria for acceptance

- Test reports with observations, measurements, and results

- Non-conformance reports if issues are found during testing, along with resolutions

These documents are vital for both quality assurance and resolving any future concerns

4. What happens if the equipment fails during FAT?

If equipment fails during FAT, it is not shipped until issues are resolved.

The manufacturer must correct any identified defects and conduct further testing to ensure that all specifications are met.

- Deviations from expected performance are documented

- Corrective actions are implemented, and retesting may occur

- The customer must approve any changes before shipment

This process ensures that only fully functional equipment is sent to the customer

5. How does FAT help mitigate risks in manufacturing?

FAT reduces risks by identifying and correcting issues before the equipment reaches the customer.

By performing comprehensive tests, manufacturers can address problems early, avoiding costly on-site repairs or delays.

- Prevents operational disruptions by resolving flaws in advance

- Enhances safety by ensuring compliance with regulatory standards

- Helps maintain project timelines and budgets by reducing post-installation issues

These practices ensure that FAT is an essential part of quality control and risk management in manufacturing.

5. What is the difference between FAT and SAT? FAT vs SAT?

FAT is performed at the manufacturer’s facility before the equipment is shipped to the customer. It verifies that the equipment functions correctly according to design specifications and contractual requirements. SAT is conducted at the customer’s site after installation to confirm that the equipment operates correctly in its actual working environment.

-

Key Objectives of FAT:

- Verify functionality before shipment.

- Identify defects in a controlled environment.

- Ensure compliance with technical specifications.

- Minimise risks of installation failures at the customer’s site.

-

Key Objectives of SAT:

- Verify installation and integration with existing systems.

- Check functionality in real-world conditions.

- Ensure operator training and documentation compliance.

- Confirm process validation and production readiness.